Repair Welding

Solid new coatings - high-quality welding results - low production costs

The process

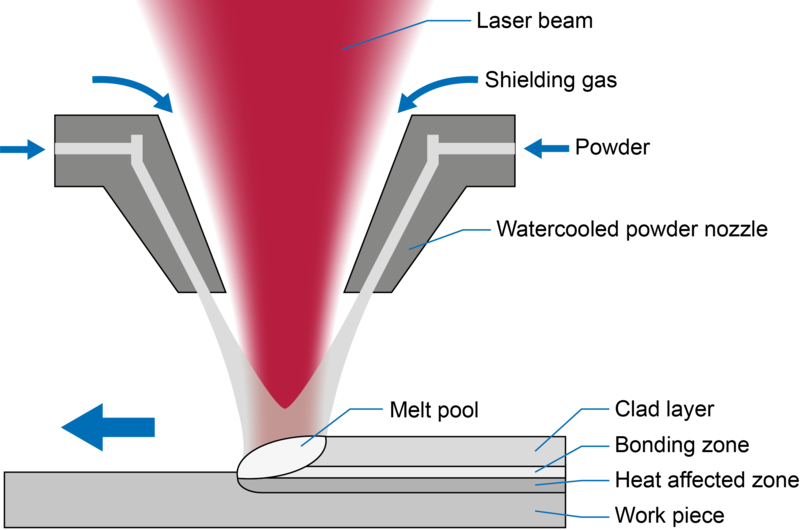

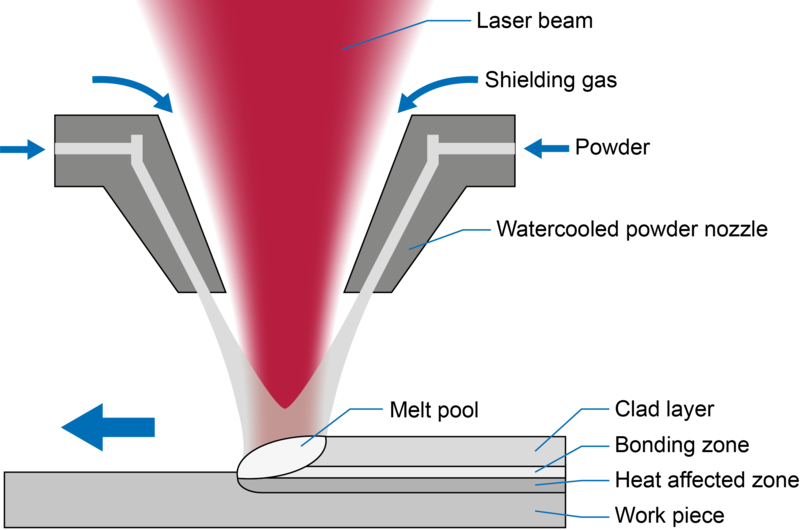

Similar to initial coating, repair welding can also be realized as wire or powder cladding. Before the processing of material, the worn coating is first removed and the workpiece surface is cleaned. The following process is largely identical with cladding. In other words, the laser beam creates a molten pool at the workpiece surface, to which a wire or powder is simultaneously added, which is then melted by the laser. In this way, within a short period of time, very solid new coatings or crack closings can be realized, at which the applied material is connected metallurgically with the basic material.

The process advantages of the diode lasers

With a diode laser, worn tools or other components are repaired or tools are remodeled with a coating layer. Firstly, the contour is prepared mechanically and then either the basic material or a harder metal in the form of powder or wire is added by laser. Examples of successful applications include repair of bearings and shafts, valve seats, and turbine blades.

The homogeneous intensity distribution in the beam of a diode laser (top-hat beam profile) causes especially molten pools. This favors the creation of high-quality surfaces that only need to be post-processed to a lesser extent. Besides, at logistically complex repair situations, the mobility compact design of the lasers turns out to be greatly advantageous.

Reparaturschweißen wird zur Wiederherstellung der Funktionsfähigkeit von Bauteilen eingesetzt. Neben Sprüngen und Rissen werden außerdem die durch Verschleiß beschädigten Beschichtungen repariert.

Application examples

Hot wire coating

Similar to initial coating, repair welding can also be realized as wire or powder cladding. Before the processing of material, the worn coating is first removed and the workpiece surface is cleaned. The following process is largely identical with cladding. In other words, the laser beam creates a molten pool at the workpiece surface, to which a wire or powder is simultaneously added, which is then melted by the laser. In this way, within a short period of time, very solid new coatings or crack closings can be realized, at which the applied material is connected metallurgically with the basic material.

The process advantages of the diode lasers

With a diode laser, worn tools or other components are repaired or tools are remodeled with a coating layer. Firstly, the contour is prepared mechanically and then either the basic material or a harder metal in the form of powder or wire is added by laser. Examples of successful applications include repair of bearings and shafts, valve seats, and turbine blades.

The homogeneous intensity distribution in the beam of a diode laser (top-hat beam profile) causes especially molten pools. This favors the creation of high-quality surfaces that only need to be post-processed to a lesser extent. Besides, at logistically complex repair situations, the mobility compact design of the lasers turns out to be greatly advantageous.

Reparaturschweißen wird zur Wiederherstellung der Funktionsfähigkeit von Bauteilen eingesetzt. Neben Sprüngen und Rissen werden außerdem die durch Verschleiß beschädigten Beschichtungen repariert.

Application examples

Hot wire coating

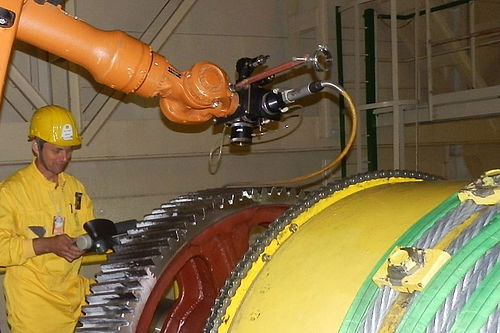

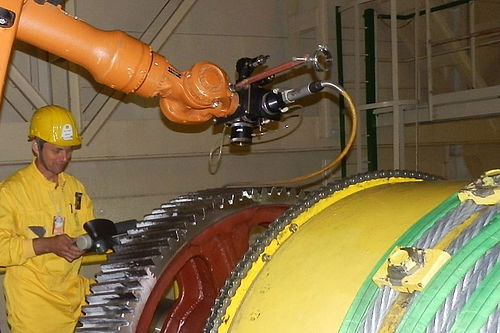

Besides damages to protective coatings, cracks in components can also require repair welding. However, such components cannot always be reached easily. For example, when the removal of a torn gear is not immediately possible, in case of doubt the laser must go to the workpiece. With Laserline's diode lasers, this is no longer a problem: these light, compact and mobile lasers can, if needed be, even be placed safely at narrow scaffoldings in lofty heights, where they can support all necessary welding works.

A mobile diode laser system LDF 3000-60 and a robot for control were installed at a height of 25 m to weld cracks in the gears.

Besides damages to protective coatings, cracks in components can also require repair welding. However, such components cannot always be reached easily. For example, when the removal of a torn gear is not immediately possible, in case of doubt the laser must go to the workpiece. With Laserline's diode lasers, this is no longer a problem: these light, compact and mobile lasers can, if needed be, even be placed safely at narrow scaffoldings in lofty heights, where they can support all necessary welding works.

A mobile diode laser system LDF 3000-60 and a robot for control were installed at a height of 25 m to weld cracks in the gears.

Similar to initial coating, repair welding can also be realized as wire or powder cladding. Before the processing of material, the worn coating is first removed and the workpiece surface is cleaned. The following process is largely identical with cladding. In other words, the laser beam creates a molten pool at the workpiece surface, to which a wire or powder is simultaneously added, which is then melted by the laser. In this way, within a short period of time, very solid new coatings or crack closings can be realized, at which the applied material is connected metallurgically with the basic material.

The process advantages of the diode lasers

With a diode laser, worn tools or other components are repaired or tools are remodeled with a coating layer. Firstly, the contour is prepared mechanically and then either the basic material or a harder metal in the form of powder or wire is added by laser. Examples of successful applications include repair of bearings and shafts, valve seats, and turbine blades.

The homogeneous intensity distribution in the beam of a diode laser (top-hat beam profile) causes especially molten pools. This favors the creation of high-quality surfaces that only need to be post-processed to a lesser extent. Besides, at logistically complex repair situations, the mobility compact design of the lasers turns out to be greatly advantageous.

Reparaturschweißen wird zur Wiederherstellung der Funktionsfähigkeit von Bauteilen eingesetzt. Neben Sprüngen und Rissen werden außerdem die durch Verschleiß beschädigten Beschichtungen repariert.

Application examples

Hot wire coating

Similar to initial coating, repair welding can also be realized as wire or powder cladding. Before the processing of material, the worn coating is first removed and the workpiece surface is cleaned. The following process is largely identical with cladding. In other words, the laser beam creates a molten pool at the workpiece surface, to which a wire or powder is simultaneously added, which is then melted by the laser. In this way, within a short period of time, very solid new coatings or crack closings can be realized, at which the applied material is connected metallurgically with the basic material.

The process advantages of the diode lasers

With a diode laser, worn tools or other components are repaired or tools are remodeled with a coating layer. Firstly, the contour is prepared mechanically and then either the basic material or a harder metal in the form of powder or wire is added by laser. Examples of successful applications include repair of bearings and shafts, valve seats, and turbine blades.

The homogeneous intensity distribution in the beam of a diode laser (top-hat beam profile) causes especially molten pools. This favors the creation of high-quality surfaces that only need to be post-processed to a lesser extent. Besides, at logistically complex repair situations, the mobility compact design of the lasers turns out to be greatly advantageous.

Reparaturschweißen wird zur Wiederherstellung der Funktionsfähigkeit von Bauteilen eingesetzt. Neben Sprüngen und Rissen werden außerdem die durch Verschleiß beschädigten Beschichtungen repariert.

Application examples

Hot wire coating

Source: Alabama Laser

Besides damages to protective coatings, cracks in components can also require repair welding. However, such components cannot always be reached easily. For example, when the removal of a torn gear is not immediately possible, in case of doubt the laser must go to the workpiece. With Laserline's diode lasers, this is no longer a problem: these light, compact and mobile lasers can, if needed be, even be placed safely at narrow scaffoldings in lofty heights, where they can support all necessary welding works.

A mobile diode laser system LDF 3000-60 and a robot for control were installed at a height of 25 m to weld cracks in the gears.

Besides damages to protective coatings, cracks in components can also require repair welding. However, such components cannot always be reached easily. For example, when the removal of a torn gear is not immediately possible, in case of doubt the laser must go to the workpiece. With Laserline's diode lasers, this is no longer a problem: these light, compact and mobile lasers can, if needed be, even be placed safely at narrow scaffoldings in lofty heights, where they can support all necessary welding works.

A mobile diode laser system LDF 3000-60 and a robot for control were installed at a height of 25 m to weld cracks in the gears.