Additive Manufacturing

There are a couple of methods for the additive manufacturing pdf of components. Laser cladding, also called laser metal deposition (direct energy deposition additive manufacturing) in this context, is in this case becoming increasingly important. It provides the possibility for creating forms and structures in a single production step with almost no material loss, post-processing or tool wear (near-net-shape manufacturing).

Manufacturing applications – overview

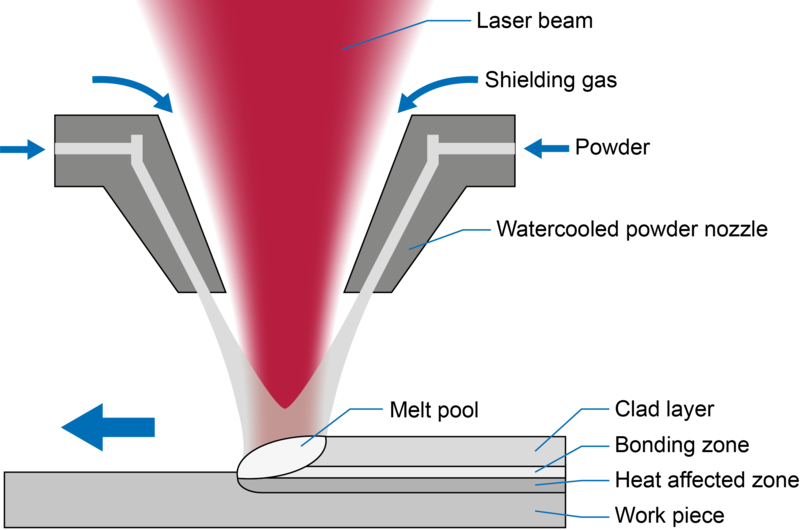

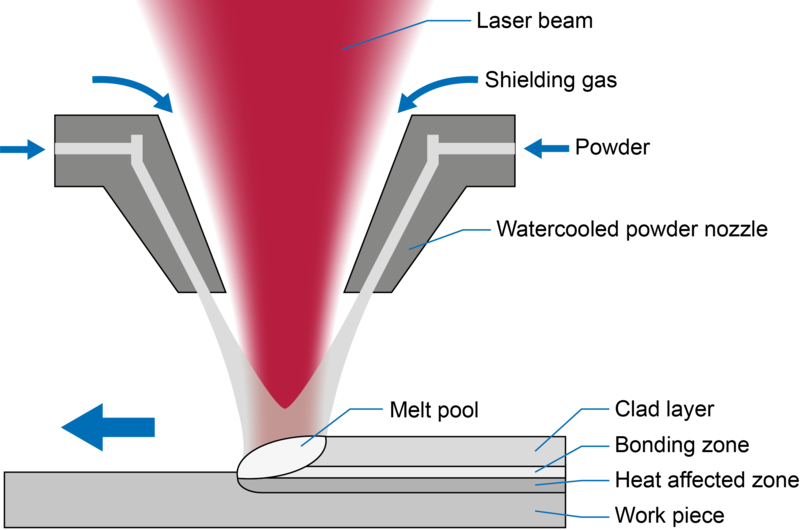

How does additive manufacturing work? The main tool of metal additive manufacturing is a system which contains a laser, a movable metal deposition head and a metal powder nozzle or wire feeder. The metal deposition head, which is suitable for 3-D printing is moved over a building platform while it adds the metal powder or the wire through heating it with the laser beam and melting it on the surface. After cooling down the material the next metal layer can be applied and so it additively generates a three dimensional part in accordance to the construction plan. The technical principle of the additive manufacturing process is basically similar to the cladding process. The difference is that there are no two-dimensional layers but rather three-dimensional forms are created.

The process advantages of diode lasers

The top-hat beam profile of Laserline's diode lasers creates very even molten pools and allows for a calm process control that leads to homogeneous, crack-free material layers. One of the most promising approaches for optimized production processes is the integration of laser beam sources in machine tools for additive manufacturing products.

Application examples

Additive manufacturing with wire feeder

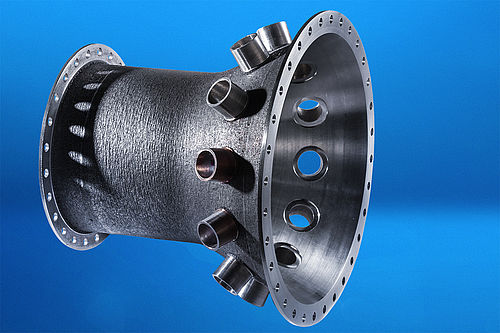

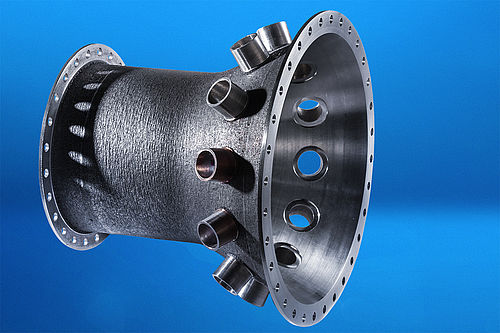

Additive manufacturing is a comparably young production method, in which a component is constructed via layer-by-layer material coating. Originally developed for prototyping, today it is mainly used for the production of geometrically complex components in small batch sizes between 1 and 1,000. Here, additive manufacturing is for the most part more economical than conventional methods.

Laser integration into machine tools

How does additive manufacturing work? The main tool of metal additive manufacturing is a system which contains a laser, a movable metal deposition head and a metal powder nozzle or wire feeder. The metal deposition head, which is suitable for 3-D printing is moved over a building platform while it adds the metal powder or the wire through heating it with the laser beam and melting it on the surface. After cooling down the material the next metal layer can be applied and so it additively generates a three dimensional part in accordance to the construction plan. The technical principle of the additive manufacturing process is basically similar to the cladding process. The difference is that there are no two-dimensional layers but rather three-dimensional forms are created.

The process advantages of diode lasers

The top-hat beam profile of Laserline's diode lasers creates very even molten pools and allows for a calm process control that leads to homogeneous, crack-free material layers. One of the most promising approaches for optimized production processes is the integration of laser beam sources in machine tools for additive manufacturing products.

Application examples

Additive manufacturing with wire feeder

Additive manufacturing is a comparably young production method, in which a component is constructed via layer-by-layer material coating. Originally developed for prototyping, today it is mainly used for the production of geometrically complex components in small batch sizes between 1 and 1,000. Here, additive manufacturing is for the most part more economical than conventional methods.

Laser integration into machine tools

One of the most promising approaches for optimized production processes is the integration of laser beam sources in machine tools. For example, Laserline's LDM diode lasers are implemented into a five-axis milling machine, where they render change between additive and subtractive processing possible: the laser realizes the powder coating while the milling head realizes the machining.

The integrated diode laser applies the powder extensively and thus creates the basic structure of the component. The downstream milling head post-processes in a chipping manner the generated part though only at necessary areas. The flexible change between laser and milling processing makes the post-processing of component segments possible, which would be out of reach at the finished part. Design and production, at which undercuts are not a problem anymore or the production of overhanging contours without support structure, are now possible. Basic new application and geometry opportunities are available.

Multiply combined applications

One of the most promising approaches for optimized production processes is the integration of laser beam sources in machine tools. For example, Laserline's LDM diode lasers are implemented into a five-axis milling machine, where they render change between additive and subtractive processing possible: the laser realizes the powder coating while the milling head realizes the machining.

The integrated diode laser applies the powder extensively and thus creates the basic structure of the component. The downstream milling head post-processes in a chipping manner the generated part though only at necessary areas. The flexible change between laser and milling processing makes the post-processing of component segments possible, which would be out of reach at the finished part. Design and production, at which undercuts are not a problem anymore or the production of overhanging contours without support structure, are now possible. Basic new application and geometry opportunities are available.

Multiply combined applications

How does additive manufacturing work? The main tool of metal additive manufacturing is a system which contains a laser, a movable metal deposition head and a metal powder nozzle or wire feeder. The metal deposition head, which is suitable for 3-D printing is moved over a building platform while it adds the metal powder or the wire through heating it with the laser beam and melting it on the surface. After cooling down the material the next metal layer can be applied and so it additively generates a three dimensional part in accordance to the construction plan. The technical principle of the additive manufacturing process is basically similar to the cladding process. The difference is that there are no two-dimensional layers but rather three-dimensional forms are created.

The process advantages of diode lasers

The top-hat beam profile of Laserline's diode lasers creates very even molten pools and allows for a calm process control that leads to homogeneous, crack-free material layers. One of the most promising approaches for optimized production processes is the integration of laser beam sources in machine tools for additive manufacturing products.

Application examples

Additive manufacturing with wire feeder

Additive manufacturing is a comparably young production method, in which a component is constructed via layer-by-layer material coating. Originally developed for prototyping, today it is mainly used for the production of geometrically complex components in small batch sizes between 1 and 1,000. Here, additive manufacturing is for the most part more economical than conventional methods.

Laser integration into machine tools

How does additive manufacturing work? The main tool of metal additive manufacturing is a system which contains a laser, a movable metal deposition head and a metal powder nozzle or wire feeder. The metal deposition head, which is suitable for 3-D printing is moved over a building platform while it adds the metal powder or the wire through heating it with the laser beam and melting it on the surface. After cooling down the material the next metal layer can be applied and so it additively generates a three dimensional part in accordance to the construction plan. The technical principle of the additive manufacturing process is basically similar to the cladding process. The difference is that there are no two-dimensional layers but rather three-dimensional forms are created.

The process advantages of diode lasers

The top-hat beam profile of Laserline's diode lasers creates very even molten pools and allows for a calm process control that leads to homogeneous, crack-free material layers. One of the most promising approaches for optimized production processes is the integration of laser beam sources in machine tools for additive manufacturing products.

Application examples

Additive manufacturing with wire feeder

Additive manufacturing is a comparably young production method, in which a component is constructed via layer-by-layer material coating. Originally developed for prototyping, today it is mainly used for the production of geometrically complex components in small batch sizes between 1 and 1,000. Here, additive manufacturing is for the most part more economical than conventional methods.

Laser integration into machine tools

One of the most promising approaches for optimized production processes is the integration of laser beam sources in machine tools. For example, Laserline's LDM diode lasers are implemented into a five-axis milling machine, where they render change between additive and subtractive processing possible: the laser realizes the powder coating while the milling head realizes the machining.

The integrated diode laser applies the powder extensively and thus creates the basic structure of the component. The downstream milling head post-processes in a chipping manner the generated part though only at necessary areas. The flexible change between laser and milling processing makes the post-processing of component segments possible, which would be out of reach at the finished part. Design and production, at which undercuts are not a problem anymore or the production of overhanging contours without support structure, are now possible. Basic new application and geometry opportunities are available.

Multiply combined applications

One of the most promising approaches for optimized production processes is the integration of laser beam sources in machine tools. For example, Laserline's LDM diode lasers are implemented into a five-axis milling machine, where they render change between additive and subtractive processing possible: the laser realizes the powder coating while the milling head realizes the machining.

The integrated diode laser applies the powder extensively and thus creates the basic structure of the component. The downstream milling head post-processes in a chipping manner the generated part though only at necessary areas. The flexible change between laser and milling processing makes the post-processing of component segments possible, which would be out of reach at the finished part. Design and production, at which undercuts are not a problem anymore or the production of overhanging contours without support structure, are now possible. Basic new application and geometry opportunities are available.

Multiply combined applications

Source: HG Laser